PHOENIX- JAIVAHINI CONSULTANCY

SOLUTION ROUND THE CORNER

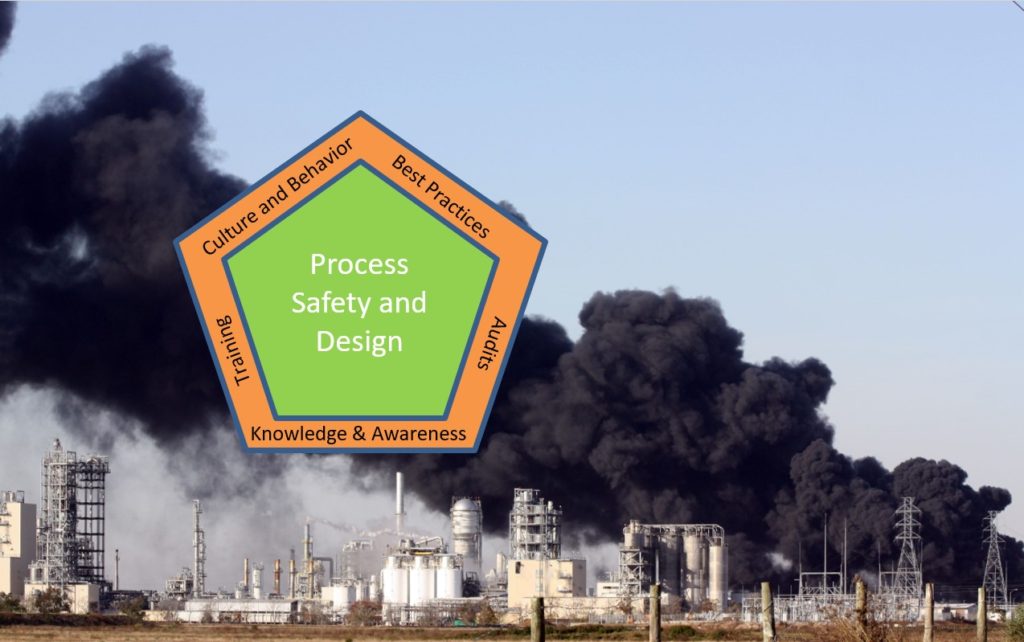

Process Safety Design & Process Safety Management

Process safety refers to the prevention of releases of process and utility materials, chemicals, energy or any other potentially hazardous materials during the course of chemical processes, which can have a serious impact on the manufacturing plant and environment.

Process safety involves, mostly, the prevention of leaks, spills, equipment malfunction, explosions due to over-pressures, over-temperatures,corrosion, metal fatigue, etc.

Process safety specialists of Jaivahini facilitate the clients so that they could develop an understanding of processes on the aspect of safety and this includes:-

1. Creating of the matrix that gives clarity on the potential dangers of the process. The dangers could arise due to materials (raw materials, intermediates, product, reaction mixtures & process masses at various stages, mother liquor, distillation/evaporation residues, powders/dusts, etc) and processes in which the materials and managed.

2. Developing a strategy for performing optimal process safety studies that include

- Screening studies for understanding roughly the quantum of potential dangers associated with the processes.

- Normal reaction studies using a reaction calorimeter, which will allow an accurate measure of not only the reaction heat to be ascertained, but also to examine how much heat is “accumulated” during the course of reaction/various additions of chemicals. In other words, you can accurately find out, how much heat could be evolved if anything went wrong.

- Consequence analysis studies using adiabatic calorimeter/dust explosion studies. Consequence analysis is an evaluation of the potential outcome from an incident if it were to happen and how the incident affects the surrounding people, machinery, equipment and environment.

3. Develop a strategy for safe operations based on the analysis of process safety studies and design/simulation of processes.

4. Implementation of safe operating strategy comprehensively developed for the whole of the process.

Jaivahini team supports the client to develop safe processes, scaled-up and commercialized. Experts at Jaivahini would provide the necessary guidance to the client’s team so that they could develop the best fit, control strategies for all the relevant process steps of any chemical process, end-to-end, i.e. right from raw material handling to product packing. We also guide to implement PSM methodology by helping the clients through training, guidelines/SOPs preparation and audits.

Separation Technologies

Jaivahini has world-class expertise in separation technologies especially in distillation, evaporation, extraction, membrane separations and adsorption/process chromatography areas. The team with its collective experience was involved in inventing, developing and commercializing at least 100 separations related technologies in its lifetime.

The team collectively has expertise in giving total integrated solution for solvent recovery plants by designing the suitable “solvent recovery process” and then developing the basic engineering package for the solvent recovery integrated process. The engineering package includes PFD, P&ID, process design of the distillation column, condenser, other static equipment with the deliverables like Process Data Sheet and GA drawings. Process optimization studies for the improvement of the efficiency of the operating Recovery Plants.

Jaivahini has specialization in specialized areas such as centrifugal extraction, rotating disc contactors, spray drying, lyophilization, fluidized bed processing/granulation, rotary vacuum thin-film evaporation as well as drying applications, short path distillation, etc.

Jaivahini team will help you in solving very intricate and complex separation problems for both impurities removal and product purification, including technology assessment and selection, design, testing and even development of totally novel and innovative solutions.

Crystallization

Crystallization is often used in the pharmaceutical industry as a separation or a purification technique especially for producing an API in the form of crystals. The present day industry has a lot of concerns related to chiral purity, polymorphism and particle size distribution (PSD). The Jaivahini team has an extensive knowledge base in both precipitation and crystallization techniques.

Jaivahini takes a step-by-step approach in solving crystallization problems. They are

- Heuristics based judgment for selection of solvents for crystallization

- Analysis on the experimental studies conducted for solvent selection

- Generation of solid-liquid equilibrium data

- Generation of solution strategy based on the product quality requirements. Any crystallization process could be controlled to be either a nucleation based or crystal growth based one.

- Application of the control strategy on the commercial operating facility

Jaivahini can help your company develop, scale-up, optimize, or troubleshoot both crystallization/precipitation processes right from providing expert consulting services for specific crystallization problems to developing comprehensive turn-key process solutions for complex or wider problems.

Quality by Design (QbD)

Quality by Design is a systematic approach to process and product development, which begins with predefined objectives for both product and process. QbD focuses, quality should be built into a product and clearly emphasizes the requirement of thorough understanding of both the product and process by which they are developed and later applied with appropriate process controls based on sound knowledge of science and quality risk management. It is important to have a clear understanding of the risks involved in manufacturing the product and also clarity on paths to be taken to mitigate those risks.

API industry has been talking a lot about the concepts of Quality by Design for the past decade. However, the implementation of QbD in the API industry is not as comprehensive or as prevalent as it is there in the formulation industry. Main reason for this lack of comprehensive QbD implementation is due to the lack of understanding of complex chemical processes, which is the precursor for application of risk-based controls. Incomplete understanding of “complex chemical kinetics of related substances” as well as “physicochemical property variations of products” that get impacted due to heat, mass and momentum transfer, during the course of processing would result in the application of false control strategies and root cause analysis (in case of process/product failures).

Jaivahini’s team of experts has got the right expertise for guiding the clients to develop process understanding for complex situations.

Jaivahini team would guide the clients

- To have a customized methodology for a systematic approach to process development based on QbD methodology.

- To have a comprehensive understanding of risk-based approach for end to end technology development, right from conceptualization to product discontinuation.

- To have elaborate awareness on the risk-based approach for selection of Critical Quality Attributes, Critical Process Parameters, Critical Material Attributes as well as the creation of design spaces, development of control strategies when working with design spaces and fine-tuning of design spaces when the processes are moved to a commercial operating scale.

Conceptual process design and techno-economic assessments

In the course of new process development, it is often important to understand the effect of reaction conditions and other key process parameters on the overall process design and economics. Optimizing the process design at an early stage can significantly cut down engineering and correction costs at later stages of technology development and transfer.

Jaivahini’s team can work with limited lab/pilot data to synthesize conceptual routes for either producing desired chemicals in an efficient way or for re-designing/optimizing existing plants. It can study the techno-economic feasibility of the routes, perform technology benchmarking and can recommend an optimal route to achieve desired objectives. It can deliver clients a conceptual design package(CDP) or review existing CDPs as well to facilitate basic/detailed engineering. Additionally, it can also collaborate with clients to generate Intellectual property which would significantly add value to the technology package.

Process Intensification / Flow Chemistry

Process intensification or industrial flow chemistry drastically improves energy and process efficiencies of chemical processes through enhanced mass and heat transfer by creating higher surface area per unit volume, application of external force fields, manipulation of time scales and combining, reaction and separation steps, in single-process equipment.

Jaivahini team would pick the right combination of process intensification equipment that are available in the market, for commercial-scale manufacturing and design the processes as per the needs of the client. Jaivahini’s design experts can design the modern modular continuous process intensified plants. Jaivahini team has developed a new, RRPM (Removable Replaceable Parameter adjustable Modular) approach for implementation of process intensification methodology for the client’s new manufacturing plants.

Process intensification could at least, potentially increase the process yields by at least 20%, reduce the operational costs by 20% and increase the production rates (quantities produced per unit volume and time) by 200%.

Environment Management

Capacity building and product range of industries have been increasing multiple folds over the years. The wastewater discharged from industries has been becoming highly complex in nature. Environmental regulations on discharge norms are also becoming stringent nowadays due to the constant public pressure. Conventional technologies have limitations in treating the complicated wastewater, discharged from industries. The treatment of municipal wastewater becomes mandatory as it contains microbial pollutants and emerging contaminants besides conventional organics.

Jaivahini has the capability of developing customized effluent treatment technologies to meet the required discharge norms. Jaivahini has unique technologies for the complete recycling of wastewater at a competitive cost without sludge production and with low input electrical energy. It also has the expertise in the management of solid waste discharged from Industries for reuse purpose or for disposal without producing secondary emissions.

CONFIDENTIALITY

Jaivahini believes in maintaining strict confidentiality and gives total assurance that proprietary information or any information shared by the clients will be with Jaivahini only and won’t reach the media, the public, other clients or industry competitors.