Phoenix Technical Services

Project Engineering Services & Turnkey Solutions

We provide detailed engineering, procurement, construction and commissioning activities along with Basic Engineering Activities.

We offer EPC solutions for greenfield projects, Brownfield Projects, Retrofit Projects and Subtle Modifications.

Our key areas of expertise include Process and Utility piping, Manufacturing and Installation of MS or SS Vessels / Tanks, Civil, Mechanical & Electrical Works, Equipment Installation and Commissioning, Industrial Instrumentation, Process Control & Automation, Compliances, Machine Safety Systems, HVAC and other Project Engineering Related areas

Manufacture of Storage and Process Vessels/Tanks

We fabricate

- Storage and Process Vessels for range of industries

- Vessels for range of temperatures (Low Temperature, Cryogenic temperature etc.) and pressures (Low Pressure, Atmospheric vessels/tanks to High Pressure spheres)

- Storage Vessels – SS Jacketed Vessel, Chemical Storage Vessel, SS Pressure Vessel, MS Pressure Vessel

- Storage Tanks – Horizontal Chemical Storage Tank, Oïl Storage Tank, Diesel Underground Storage Tank, Air Receiver Storage Tank etc.

We perform Fabrication Service – SS Tank Fabrication Service, MS Tank Fabrication Service, Oil Storage Tank Fabrication Service, Diesel Storage Licensing Service and Turnkey Fabrication Projects.

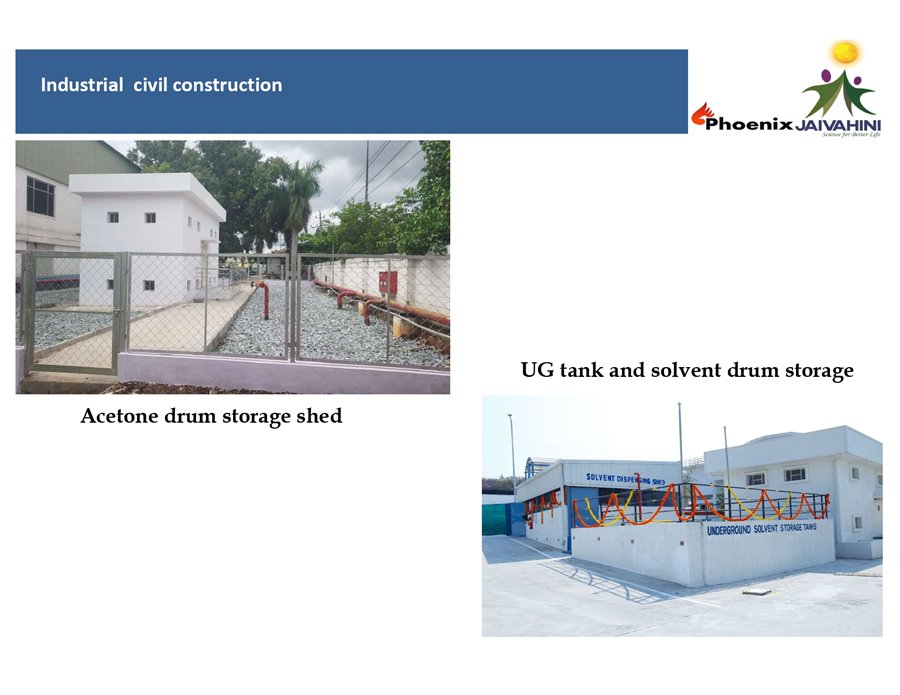

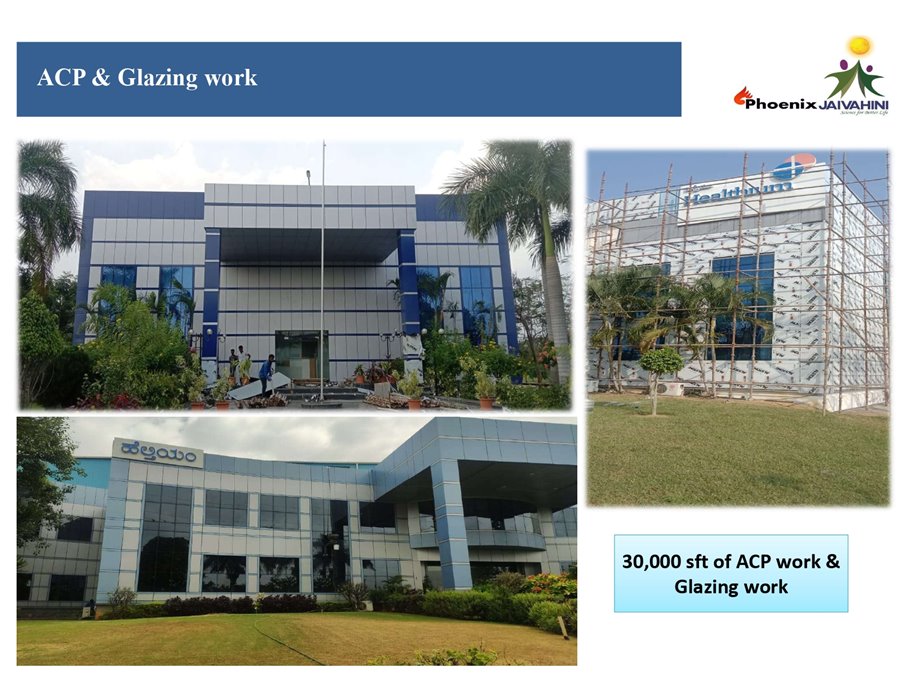

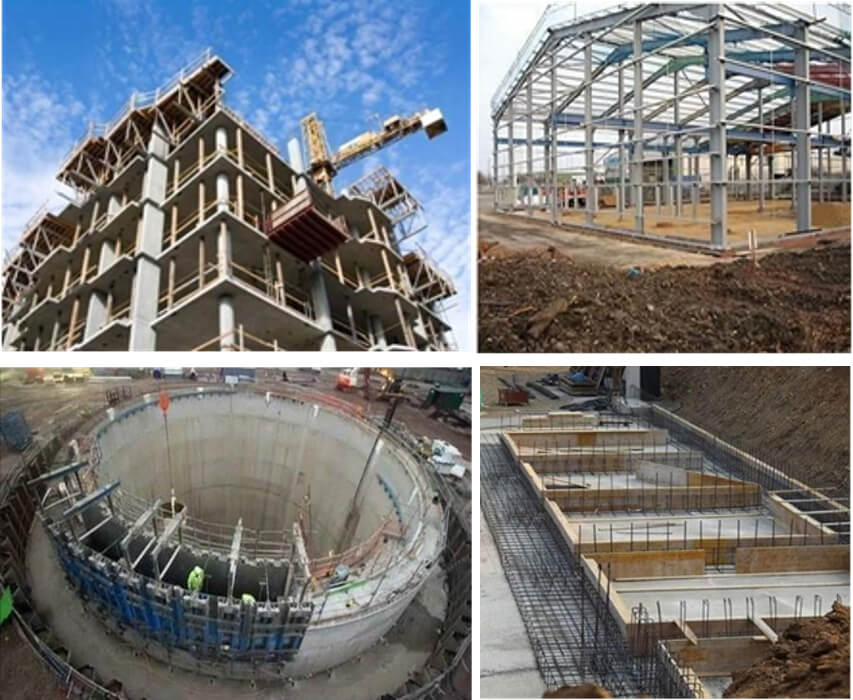

Industrial Civil and Construction Work

- Civil Planning, Estimation, Structural Design and Detailing Works

- Interior Design

- All kinds of Building Constructions (Civil and Structural) and Painting Works

- High Rise Building Painting and All kinds of Paint Jobs

- Glass Works, Vinyl, Epoxy, PU, Tile, marble and granite flooring Jobs

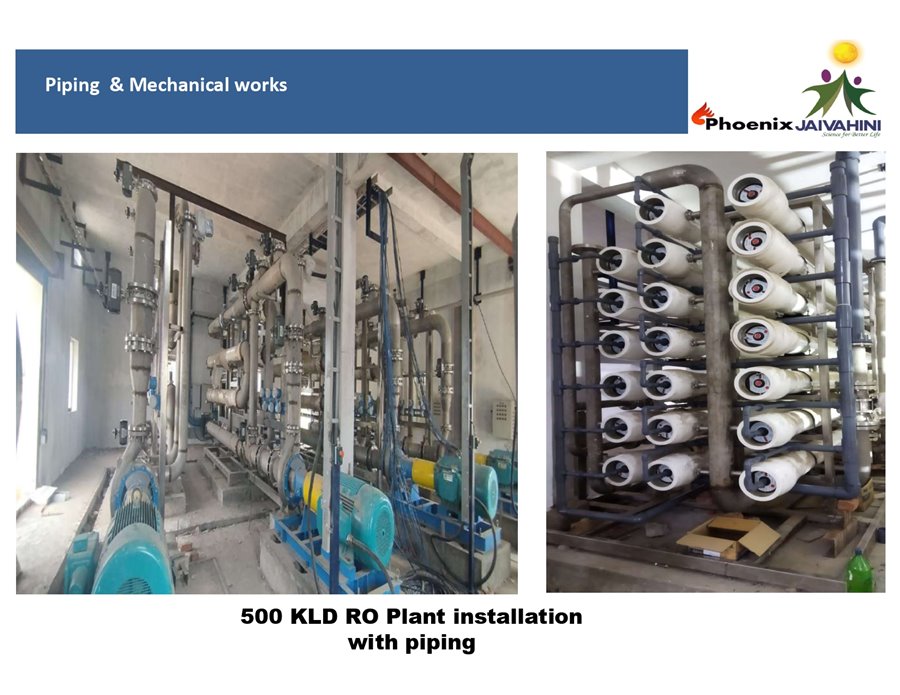

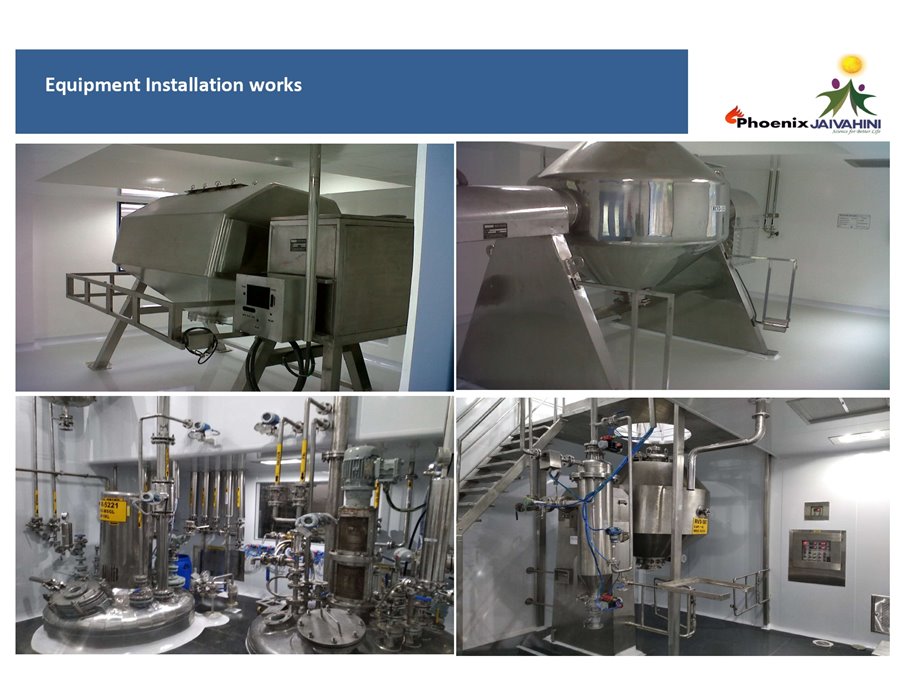

Mechanical Work

We do

- Greenfield Projects and Turnkey Projects

- Mechanical fabrication of Process, Utility and Fire Hydrant related Piping Systems

- Onsite and Offsite Structural and Equipment Manufacturing Works

- Shutdown and Maintenance, Equipment Installation and Commissioning Works.

- All types of SS, MS and GI Pipeline Works and specially for utilities like Water, Air, Diesel, Vacuum, Steam, IBR (Inverter-Based Resource) and Non IBR etc.

- Mechanical Erection in Industries (Chemical, Pharmaceutical, Specialty Chemicals, Automotives etc.)

- All kinds of Insulation for Pipelines like Nitrile Rubber, Rockwool, Aluminium Cladding etc.

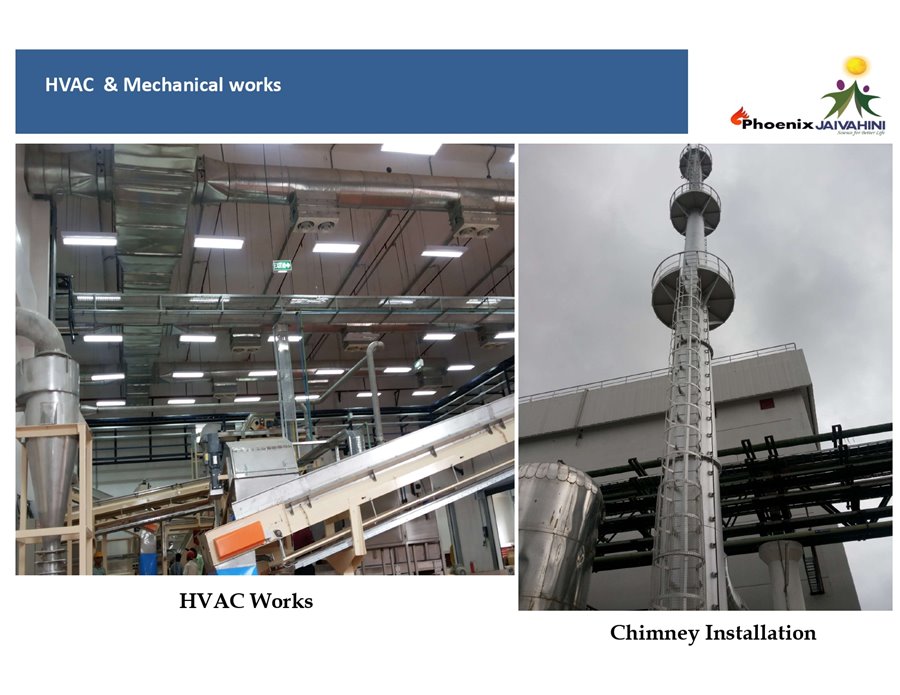

Heating, Ventilation and Air Conditioning (HVAC)

We adopt a systematic approach towards HVAC sizing, taking into consideration various factors such as Climate, Building Configuration, Space Usage, System & Area Zoning and Cleanroom Classification

Our team has experience working in an integrated way, with Architects, Process Areas Owners/Plant Managers, Consultants and other Contractors to deliver the highest quality HVAC products within specifications and on schedule.

We have a qualified group of HVAC engineers for designing state of the art AHU systems along with top end automation

Clean Room Design

- Conceptual Design for a suitable Area Classification

(Class100/1000/10000/One Lac and Socially Clean)

- Designing of the Plant Layout for different Area Classification

- Designing the Clean Room Equipment

- Preparing the Procurement Specification for the Clean Room Equipment

- Suggesting suitable panels for specific Clean Room Environment

- Designing the Validation and Commissioning Protocol

- Monitoring and Guiding of the Erection, Validation and Commissioning of the new facility

- Construction of Clean Room and its Equipment Fabrication

Utility Piping & Fire Fighting Systems

- We design Fire Fighting Systems and supply, maintain and service all kinds of fire fighting equipment, fire alarms and detection systems

- We design Safety Systems based on the Norms, Guidelines and Regulations as laid down by NSC and other international bodies such as OSHA, NFPA and HSE

- We have dedicated Piping Engineers Team who design piping for Fire Safety Systems, Chilled Water, Brine, Hot Water, Drinking Water, Steam, Cooling Water etc.

- We are experts in Customized Piping Design done as per client’s requirements

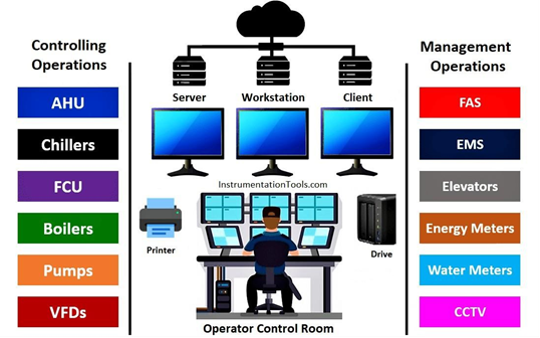

Integrated Building Management System (IBMS)

- We provide integrated solutions for building facilities encompassing monitor & control of Temperature, Pressure, RH, indoor air quality, airborne particulate count (for ISO classified areas)

- We design Building Management Systems based on open protocols like Lonworks, BACnet, and Modbus along with the 21 CFR Part 11 compliant software and documentation as per GAMP

- We ensure facility managers are well set for audit of USFDA, UKMHRA, MCC, and TGA

- We take responsibility for design, supply, installation, commissioning and maintenance, offering End-to-End solutions with assurance of energy management and comfort throughout the life-cycle of the building

Qualification and Documentation

We provide

Comprehensive Solutions in the area of Facility & Equipment Qualification and Regulatory Validation in Pharma/Life Sciences Industries.

Our Approach to validation is based on the latest industry standards/guidelines such as GAMP5, ASTM E2500 and ICH, 21 CFR part 820. Ours is a consolidated and practical risk based approach with a focus on complying with the regulatory requirements.

We focus on

- Regulatory Compliances

- Qualification and Documentation of Pharmaceutical Process Equipment, Utility and Purified Water Systems

- Computerized System Validations, PLC Validations